Recently installed interior solar shades in Intensive Care Unit. Hospital ICU’s are challenging environments. These high pressure units are full time operations with lots of uncertainty and very sick patients. Working as an outside vendor in any ICU requires a full appreciation of flexibility, cleanliness and an absolute understanding of patient safety. This was the playing field when InSync Solar was approached by the Memorial Sloan Kettering Cancer Center to install motorized shades on the entire 11th floor ICU. During the measurement process our team had to “suit up” in full surgical gear to enter each occupied room. This was repeated 20 times going through a full disinfection protocol for each room. As the project progressed we were asked to integrate the shades with a Pillow Speaker System that was being upgraded to include shade control for patient comfort.

During the measurement process our team had to “suit up” in full surgical gear to enter each occupied room. This was repeated 20 times going through a full disinfection protocol for each room. As the project progressed we were asked to integrate the shades with a Pillow Speaker System that was being upgraded to include shade control for patient comfort.

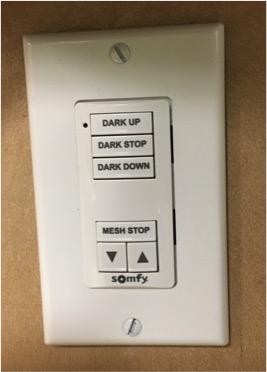

This seemingly small request required re-engineering the entire control topology. Only 2 buttons were available for full control of both the blackout shades and the solar mesh shades. This meant a sequential switch mode needed to be created for the controller on the patient bed. In addition to this challenge we could not place more than 12 volts at less than 4 milliamps into this patient controller. This was a hard engineering requirement that could not be ignored. After considerable design effort we reduced the potential patient exposure to less than 5 volts and .2 milliamps. These numbers were well below the hospital’s safety standards. Next we determined that 120 volt motors presented a theoretical risk to both staff and patients. 24 volt DC shade motors and controls were used to mitigate the risk. The power supply needed fully certified transformers that were rated “inherently safe” as well as fault tolerant with auto shut down. This meant a maximum level of safety for unlikely situation where someone would come into contact with the working power supply and wiring.

After considerable design effort we reduced the potential patient exposure to less than 5 volts and .2 milliamps. These numbers were well below the hospital’s safety standards. Next we determined that 120 volt motors presented a theoretical risk to both staff and patients. 24 volt DC shade motors and controls were used to mitigate the risk. The power supply needed fully certified transformers that were rated “inherently safe” as well as fault tolerant with auto shut down. This meant a maximum level of safety for unlikely situation where someone would come into contact with the working power supply and wiring.

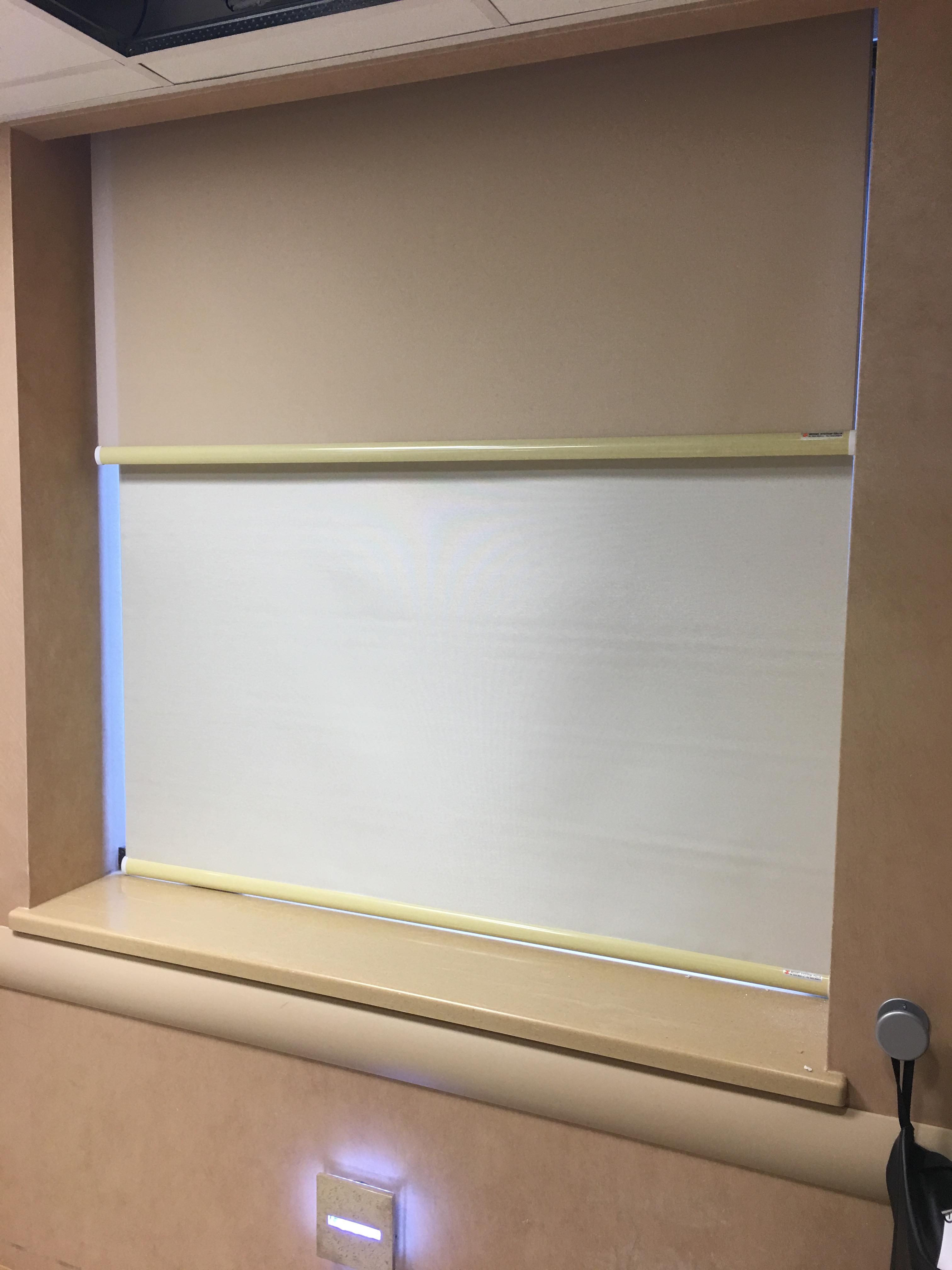

The selection of shade cloth was next on the list. The material needed to be completely PVC free with no off gassing. There could be no lead or hazardous materials sometimes found in off brand shade cloth. All of the cloth needed to be GreenGuard Certified for environmental air quality, fully flame resistant, bacterial and fungal resistant, and finally fully recyclable. There needed to be effective glare and light control with the associated energy savings along with being cleanable for infection control.

With the technical mandates satisfied the next huddle was the actual installation. We first had to co-ordinate the entire process with the low voltage wiring contractor, hospital electricians, nursing staff and supervising doctors. With rooms at a premium the full installation process for each room had to be completed in a 12 hour cycle. Our entire team was given 12 hours’ notice to be on site when a room was blocked out for work. Canceling the installation was always at the hospital’s discretion as they had little warning for emergency situations.

At times the process was daunting but it evolved into a well-oiled system to complete each room as it became available. The doctors and staff appreciate the ability to control the shades from observation areas without actually having to go in the room to disturb the patients. The patients were empowered to control a vital part of their environment in a simple and satisfying way. Lots of smiles in the stressful world of a hospital ICU.

{{cta(‘7fc41619-393a-44f3-bfac-65f105d8a90e’,’justifycenter’)}}