Interview with Brian Foley of Serge Ferrari Fabrics

Serge Ferrari is the worldwide leader in exterior fabrics for exterior solar shades. To learn more I had the pleasure to interview Brian Foley, the Regional Manager of the Northeast, Unites States. Brian has been with Serge Ferrari for nine years.

NG: Can you tell me about Serge Ferrari – its history and what markets its serves?

BF: Ferrari Textiles, was founded by Serge Ferrari in 1974. Ferrari Textiles was rebranded to Serge Ferrari in 2012. Its cooperate headquarters and manufacturing facilities are located in La Tour du Pin, France. There are two additional manufacturing facilities in Switzerland. Serge Ferrari’s recycling facility, Texyloop, is in Italy as well as fourteen additional offices and stocking warehouses throughout the world, including Pompano Beach, Florida.

Serge Ferrari is a leader in the “flexible composite material” sector. Their corporate mission is to ensure a global offering to meet tomorrow’s major challenges, such as: sustainable construction, energy control, protection and renewal of resources.

Serge Ferrari is a vertically integrated company mastering all the production steps from product development to recycling, raw material formulation, process and mechanical engineering, spinning, formulation, coating and extrusion; logistics and recycling of end of life products.

The company offers solutions to the demands for countless markets with products designed for: acoustic solutions, composite building skins, solar protection, bio-climatic façade, breathable membranes, modular structures, visual communication, indoor & outdoor furniture, yachting protection, environmental protection and specialty membranes.

NG: The Precontraint process is an exclusive offering of Serge Ferrari. Can you tell me why this is a superior fabric for exterior shading solutions?

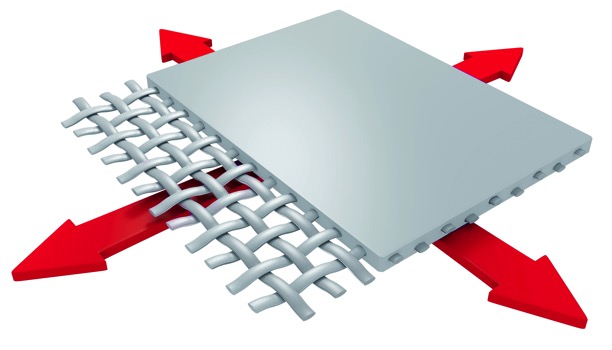

BF: Precontraint is patented technology developed by Serge Ferrari. We offer a number of different products utilizing Precontraint technology. Precontraint allows Serge Ferrari to apply equal tension across the WARP (length) and WEFT (width) throughout the entire coating process giving our products superior dimensional stability.

In terms of shading solutions Precontraint provides a number of unique advantages for a number of different  applications. With regards to the commercial awning and the pergola markets, Precontraint products are an obvious choice due to their ability to protect against UV degradation and abrasion. Precontraint also allows the fabric to lay flat allowing better welds. The reason most often given of why to use a Precontraint product is the dimensional stability.

applications. With regards to the commercial awning and the pergola markets, Precontraint products are an obvious choice due to their ability to protect against UV degradation and abrasion. Precontraint also allows the fabric to lay flat allowing better welds. The reason most often given of why to use a Precontraint product is the dimensional stability.

Interior and exterior shade applications will also benefit from using Precontraint. Soltis, one of the many Precontraint products is designed specifically for these applications. The fact that Precontraint fabrics are woven first and then coated creates thinner and lighter options, which allows more fabric into a smaller cassette, which will potentially reduce the size of the motor. The dimensional stability prevents edge curling and will not require resetting of limit switches.

NG: How do you see the growth of the exterior shading solutions in the US market?

BF: There is tremendous growth in the exterior shade market in the United States. As people and companies look to reduce energy costs this market is starting to become an obvious win. Serge Ferrari products are excellent at reducing solar heat gain and glare while also providing an aesthetic benefit due to the wide choice of fabric color options.

{{cta(‘ab5bb3dd-773c-4050-8381-b32aefdf2821’)}}